Ethercat Stepper Driver Manufaturer

Introduction

Our Fieldbus series high-performance stepper drive has better design and stability, supports 485, EtherCAT, Mod bus TCP, CANopen, and other fieldbus communication methods, can be connected to multi-axis networking, and is easy to use.

Rtelligent’s EtherCAT stepper driver is a cutting-edge solution for high-performance motion control in industrial automation. This driver leverages EtherCAT, a real-time industrial Ethernet communication protocol, to enable rapid data exchange between devices in a distributed control network.

EtherCAT stepper drivers offer precise positioning and synchronization, making them ideal for demanding applications in manufacturing, robotics, and machinery. They provide flexibility, scalability, and reduced cabling complexity in multi-axis systems, optimizing efficiency and simplifying control.

With EtherCAT technology, these drivers ensure seamless integration, real-time data transmission, and accurate motion control, empowering industries with advanced automation solutions.

Naming Rule

EC

1

T

2

60

3

-

◻

5

- Fieldbus type

N: 485 communication

EC: EtherCAT communication - Series code

R: open loop

T: closed loop - Matching motor frame size

- Non standard code

*Model naming rules are only used for model meaning analysis.

For specific optional models, please refer to the details page.

Modbus RTU NTSeries

- Matching motor frame below 86mm

- Integrated motion controller function

- Built-in T-shaped acceleration and deceleration

- Support torque homing

- Compatible control/pulse control/switch control

Modbus TCP EPSeries

- Matching motor frame below 60mm

- Integrated motion controller function

- Built-in T-shaped

- Support torque homing

- Compatible with 1OM/1OOMbps etwork interface

EtherCAT ECSeries

- Matching motor frame below 86mm

- Comply with CiA402 specification

- CSP/CSV!HM/PP/PV

- Support torque homing

- The minimum synchronization period in CSP mode is 200us

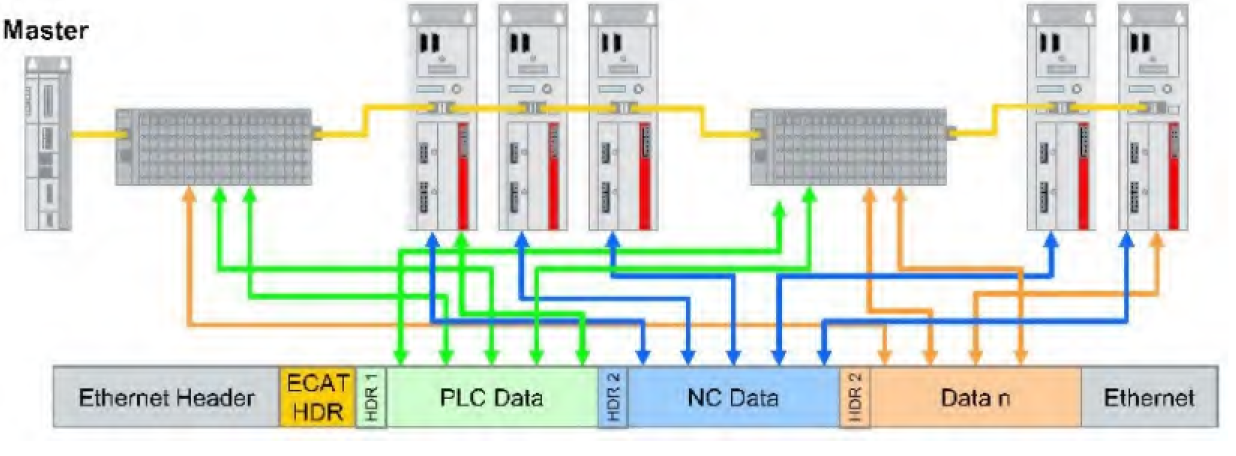

EtherCAT Protocol: Based on Industrial Ethernet Fieldbus communciation

EtherCAT Principle

FEATURES

• Effident transmission mechanism and speed

• Aexible network topology

• Automatic node address configuration for easy maintenance

• Open technology

• Simple hardware, high cost performance

• Suitable for modular collaborative development

EtherCAT Protocol: Based on Industrial Ethernet Fieldbus communciation

EtherCAT Principle

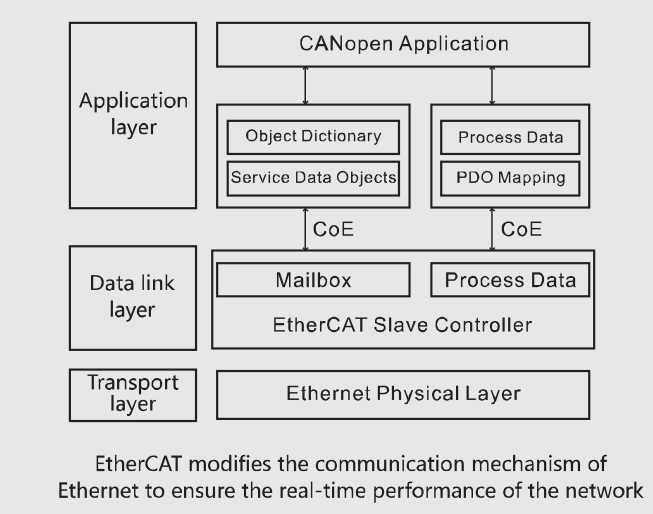

CiA402 control mode

- Profile sition Mode (PP): Set position, speed, accelenrtion and deceleration parameters, and execute relative or absolute position commands from the internal buffer of the drive.

- Profile Velocity Mode (PV): Set speed, acceleretlon and deceleration parameters, and execute the speed command by the internal buffer of the drive on commands from the internal buffer of the drive.

- Cyclic Synchronous Position Mode (CSP) The main controller generates a position trajectory and sends the target position (0X607A) to the drive in each PDO update cycle.

- Homing Mode (HM) Support No.17-30, No.35 homing modeThe ralevant parameters need to be set according to the format

- Process Data Object (PDO): Process data object Used to transmit real-time data Configure the relevant parameters of the driver as PDO parameters, and realize real-time reading and writing of status and commands between the master station and the slave station in each synchronization cycle For example, parameter such as target position in CSP mode

- Service Date Object (SDO): Service Deta Objects Used to configure static parameters, Configure the driver parameters that do not need to be changed in real time as SDO parameters, and set the relevant parameters of the slave driver on tha master station. For example, working current and other parameters.

PDO and SDO parameters

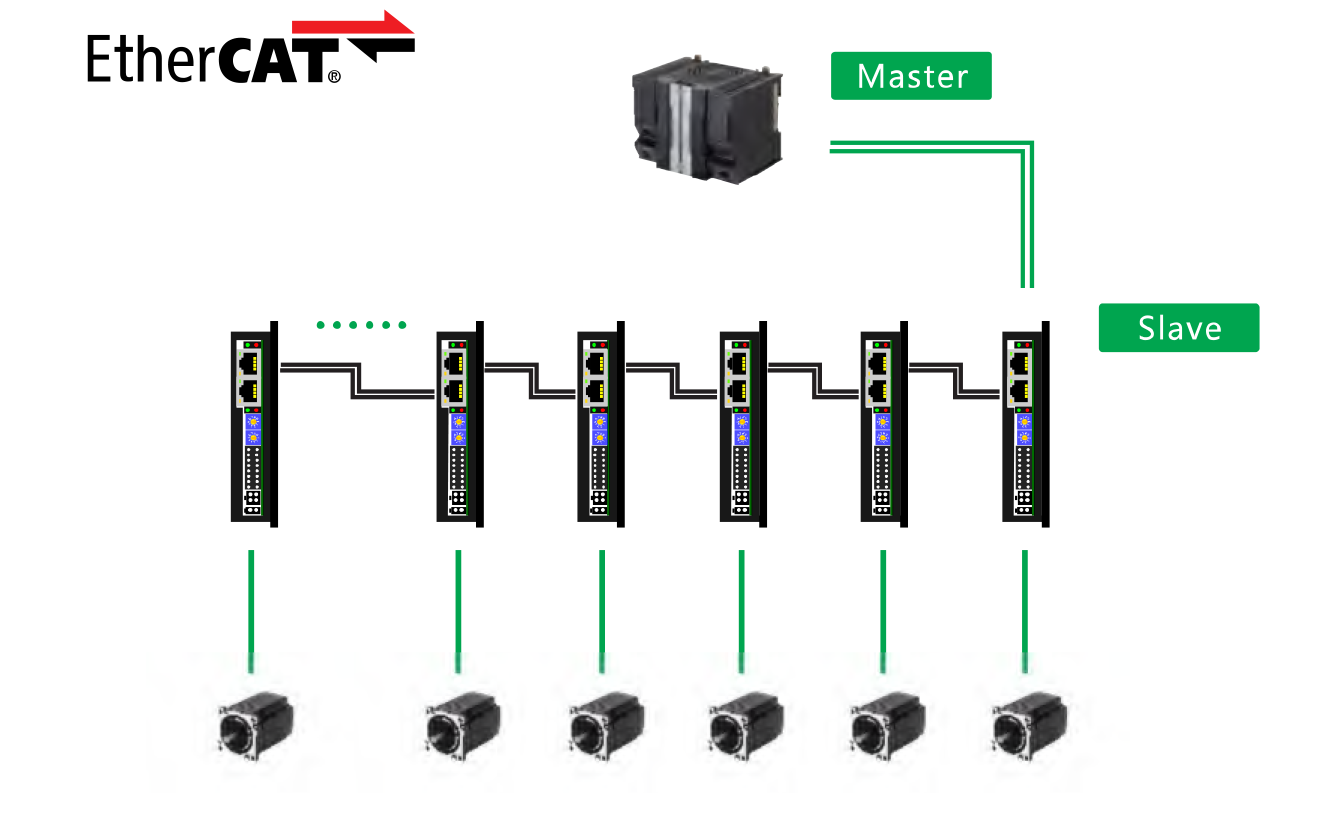

Ether CAT Network Diagram

Technical specification

| Model | Peak current A | Weight kg | Input voltage | Dimensions | Input & output | Matching motor |

|---|---|---|---|---|---|---|

| ECR42 | 2.5 | 0.4 | 18-80\IDC | 132X82X29 | Six inputs, two outputs | open loop below 42mm |

| ECR60 | 6.0 | OA | 18-80\IDC | 132X82X29 | Six inputs, two outputs | open loop below 60mm |

| ECR86 | 72 | 0.6 | 1s-8INN:. | 151X97X35 | Six inputs, two outputs | open loop below 86mm |

| ECT42 | 3.0 | OA | 18-80\IDC | 132X82X29 | Four inputs, two outputs | closed loop below 42mm |

| ECT60 | 62 | 0.4 | 18-80\IDC | 132X82X 29 | Four inputs, two outputs | closed loop below 60mm |

| ECR60X2 | 6.0 | 0.5 | 18-80\IDC | 175X98X33 | Eight inputs, four outputs | open loop below 60mm |

ECR Series

Introduction

The EtherCAT fieldbus stepper drive ECT60X2/ECR60X2 is based on the CoE standard framework and complies with the CiA402 standard. The data transmission rate is up to 1OOMb/s, and supports various network topologies. ECR42 matches open loop stepper motors below 42mm. ECR60 matches open loop stepper motors below 60mm. ECR86 matches open loop stepper motors below 86mm.

• Control mode: PP, PV. CSP, HM, etc

• Power supply voltage: 18-BOVDC (ECR60), 24-1OOVDC/18-SOVAC (ECR86)

Input and output: 2-channel differential inputs/4-channel 24V common anode inputs; 2-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment solar equipment, 3C electronic equipment etc

ECT Series

Introduction

The EtherCAT fieldbus stepper drive is based on the CoE standard framework and complies with the CiA402 standard. The data transmission rate is up to 1OOMb/s, and supports various network topologies. ECT42 matches closed loop stepper motors below 42mm. ECT60 matches closed loop stepper motors below 60mm. ECT86 matches closed loop stepper motors below 86mm.

• Control mode: PP, PV, CSP, HM, etc

• Power supply voltage: 18-SOVDC (ECT60), 24-1OOVDC/18-SOVAC (ECT86)

•Input and output: 4-channei24V common anode input; 2-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment, solar equipment, 3C electronic equipment, etc

ECT60X2/ECR60X2

Introduction

The EtherCAT field bus stepper drive ECT60X2/ECR60X2 is based on the CoE standard framework and complies with the CiA402 standard. The data transmission rate is up to 1OOMb/s, and supports various network. topologies. ECT60X2 matches closed loop stepper motors below 60mm. ECR60X2 matches open loop stepper motors below 60mm.

• Control mode: PP, PV. CSP, HM, etc

• Power supply voltage: 18-BOVDC

• Input and output: 8-channel 24V common anode input; 4-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment solar equipment, 3C electronic equipment etc

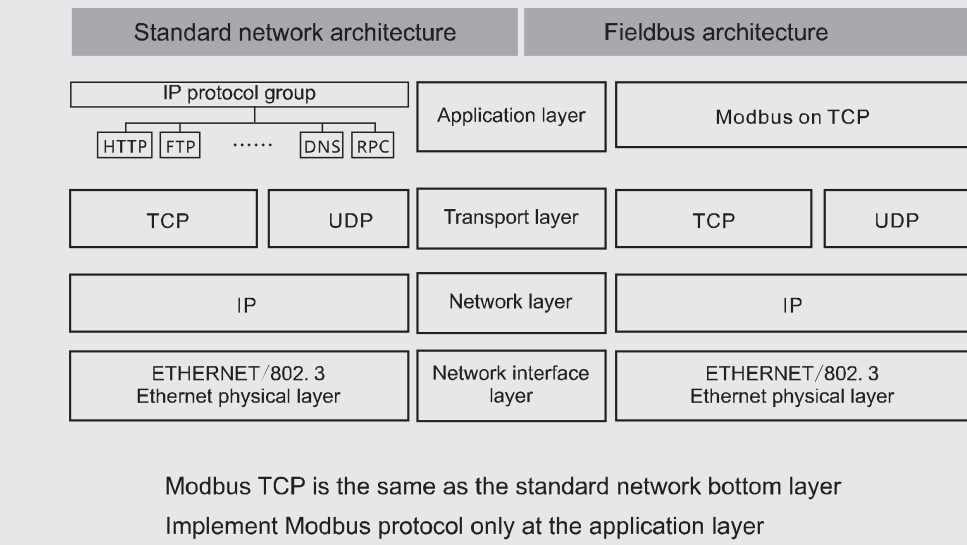

Modbus TCP Communication Type Stepper Drive

Protocol Overview

FEATURES

• Compatible with standard Ethernet

• Cost effective of network implementation

• Easy to interconnect with various systems

• High-speed data transfer rate

• Mature supporting equipment

• Convenient for remote debugging and monitoring

TCP Network Connection Diagram

EP Series Network Connection Diagram

Technical specifications

| Model | Peak Current A | Weight Kg | Power voltage | Dimensions mm | Communication mode | Maximum baud rate | Matching motor |

|---|---|---|---|---|---|---|---|

| EPR60 | 6.0 | 0.4 | 18-50VDC | 134X82X29 | TCP/IP | 10M/100M | Oprn loop below 60mm |

| EPR60 | 6.0 | 0.4 | 18-50VDC | 134X82X29 | TCP/IP | 10M/100M | Oprn loop below 60mm |

EPR60

Introduction

The Ethernet fieldbus-controlled stepper drive EPR60 runs the Modbus TCP protocol based on standard Ethernet interface and integrates a rich set of motion control functions. EPR60 adopts standard 10M/100M bps network layout, which is convenient to build the Internet of Things for automation equipment. EPR60 is compatible with open-loop stepper motors base below 60mm.

• Control mode: fixed length/fixed speed/homing/multi-speed/multi-position

• Debugging software: RTContigurator (USB interface)

• Power voltage: 18-SOVDC

• Typical applications: assembly lines, warehousing logistics equipment multi-axis positioning platforms, etc

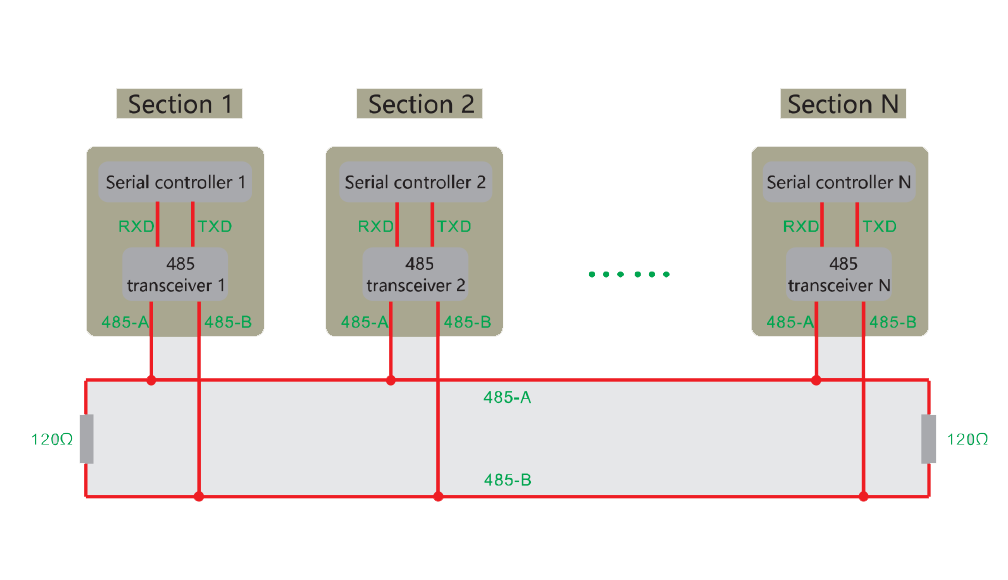

RS485

485 Communication Type Stepper Drive

Modbus RTU Rotocol Overview

FEATURES

• Broadcast mode

•One master multiple slaves

• Host query and slave response

•Slaves have no priority arbitration rights

•Simple hardware

• Reliable serial communication

Network Diagram

Two wire Half duplex wiring diagram

NT60

Introduction

485 fieldbus stepper drive NT60 is based on RS-485 network to run Modbus RTU protocol. The intelligent motion control function is integrated, and with external IO control, it can complete functions such as fixed position/fixed speed/multi position/auto-homing. NT60 matches open loop or closed loop stepper motors below 60mm.

• Control mode: fixed length/fixed speed/homing/multi-speed/multi-position

• Debugging software: RTConfigurator (multiplexed RS485 interface)

• Power voltage: 24-SOV DC

• Typical applications: single axis electric cylinde assembly line, connection table, multi-axis positioning platform, etc

NT86

Introduction

485 field bus stepper drive NT60 is based on RS-485 network to run Modbus RTU protocol. The intelligent motion control function is integrated, and with external IO control, it can complete functions such as fixed position/fixed speed/multi position/auto-homing. NT86 matches open loop or closed loop stepper motors below 86mm.

• Control mode: fixed length/fixed speed/homing/multi-speed/multi-position/potentiometer speed regulation

• Debugging software: RTConfigurator (multiplexed RS485 interface)

• Power voltage: 18-11OVDC, 18-80VAC

• Typical applications: single axis electric cylinder, assembly line, multi-axis positioning platform, etc